Trimmer Potentiometers: Core Functional Technology and ApplicationsTrimmer potentiometers, such as the CFR-50JB-52-1K3, are compact, adjustable resistors that play a vital role in fine-tuning electronic circuits. Their ability to provide precise resistance adjustments makes them essential in a wide range of applications. Below, we delve into the core functional technologies, relevant articles, and application development cases that showcase the effectiveness of trimmer potentiometers.

Core Functional Technology1. Basic Operation2. Types of Trimmer Potentiometers3. Adjustment Mechanism4. Applications1. "Understanding Potentiometers: Types and Applications"2. "The Role of Trimmer Potentiometers in Circuit Design"3. "Calibration Techniques Using Trimmer Potentiometers"1. Audio Equipment Calibration2. Sensor Calibration in Industrial Applications3. Power Supply Voltage Adjustment4. Consumer Electronics Articles on Trimmer Potentiometers Application Development Cases ConclusionTrimmer potentiometers, exemplified by the CFR-50JB-52-1K3, are integral components in the design and functionality of electronic devices. Their ability to provide precise adjustments enhances the performance of various applications, from audio equipment to industrial sensors. A thorough understanding of their technology and applications can lead to improved design choices and enhanced product performance, making trimmer potentiometers indispensable in modern electronics.

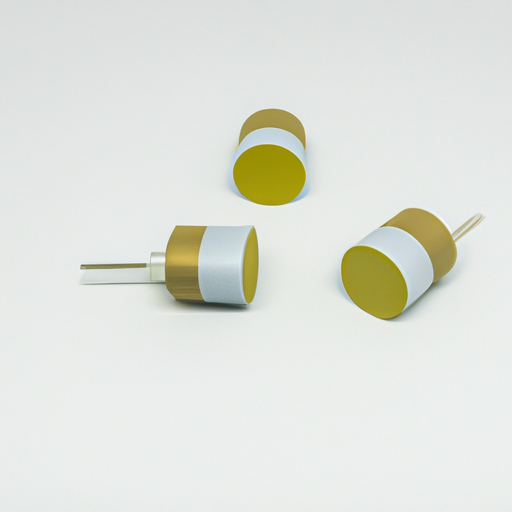

CFR-25JB-52-1M2 Adjustable Inductors: Core Functional Technology and Application DevelopmentIntroduction to Adjustable Inductors

Adjustable inductors, such as the CFR-25JB-52-1M2, are critical components in a wide range of electronic circuits, enabling designers to fine-tune inductance values to meet specific requirements. These inductors are particularly valuable in applications where variable inductance is essential for optimal performance, including RF circuits, filters, and oscillators. Core Functional Technology1. Variable Inductance Mechanism2. Material Composition3. Tuning Range4. Temperature Stability5. Compact Design1. RF Circuit Design2. Filter Design3. Power Supply Regulation4. Signal Processing5. Educational and Research Applications Application Development Cases ConclusionThe CFR-25JB-52-1M2 adjustable inductor exemplifies the significance of variable inductance in modern electronic design. Its core functional technologies, including variable inductance mechanisms, high-quality material composition, and temperature stability, make it a valuable component across various applications. From RF circuit design to power supply regulation, the versatility of adjustable inductors continues to drive innovation in electronic systems. As technology advances, the role of adjustable inductors is expected to expand, further enhancing their importance in the electronics industry.

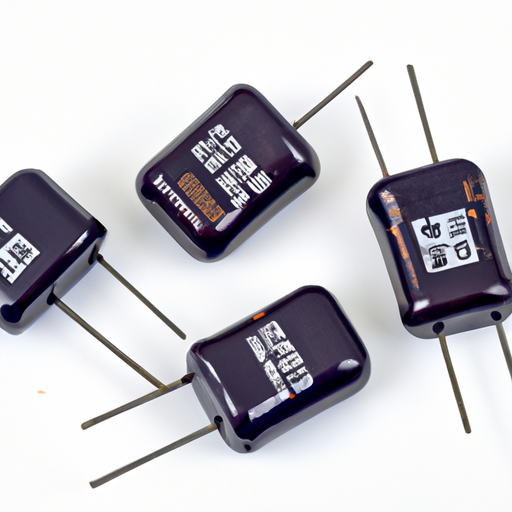

Application Development in Aluminum-Polymer Capacitors for CFR-25JB-52-1K2: Key Technologies and Success StoriesAluminum-polymer capacitors, such as the CFR-25JB-52-1K2, are increasingly favored in various electronic applications due to their advantageous characteristics, including high capacitance, low equivalent series resistance (ESR), and excellent thermal stability. Below, we explore the key technologies that underpin their development and highlight notable success stories across different industries.

Key Technologies1. Electrolyte Formulation2. Anode and Cathode Materials3. Manufacturing Techniques4. Thermal Management5. Simulation and Modeling6. Integration with Other Components1. Consumer Electronics2. Electric Vehicles (EVs)3. Renewable Energy Systems4. Industrial Automation5. Telecommunications Success Stories ConclusionThe development and application of aluminum-polymer capacitors like the CFR-25JB-52-1K2 are driven by significant advancements in materials science, manufacturing techniques, and integration capabilities. Their success across diverse industries underscores their versatility and critical role in modern electronic systems. As technology continues to evolve, further innovations in this field are anticipated, leading to even more efficient and reliable capacitor solutions that will support the next generation of electronic devices and systems.

Overview of Silicon Capacitors: CFR-50JB-52-1K2Silicon capacitors, exemplified by the CFR-50JB-52-1K2 model, represent a transformative leap in capacitor technology, particularly suited for applications demanding high reliability, compactness, and superior performance. This overview highlights the core functional technologies and application development cases that underscore the effectiveness of silicon capacitors.

Core Functional Technologies1. Silicon-Based Dielectric Material2. Miniaturization3. High Capacitance Density4. Integration with Integrated Circuits (ICs)5. Temperature Stability6. Low Leakage Current1. Consumer Electronics2. Automotive Applications3. Telecommunications4. Medical Devices5. Industrial Automation6. Renewable Energy Systems Application Development Cases ConclusionSilicon capacitors, such as the CFR-50JB-52-1K2, are leading the way in capacitor technology, offering significant advantages in size, performance, and reliability. Their diverse applications across various industries—from consumer electronics to automotive and renewable energy—demonstrate their versatility and effectiveness in meeting the evolving demands of modern electronic systems. As technology advances, the role of silicon capacitors is expected to expand, driving further innovations in electronic design and application development.

Application Development in Niobium Oxide Capacitors for CFR-50JB-52-1R2: Key Technologies and Success StoriesNiobium oxide capacitors, particularly exemplified by the CFR-50JB-52-1R2 model, represent a significant leap in capacitor technology. Their unique properties make them suitable for a wide range of applications across various industries. Below is an overview of the key technologies that underpin their development and notable success stories that highlight their application.

Key Technologies1. High Dielectric Constant 2. Temperature Stability 3. Low Leakage Current 4. High Voltage Ratings 5. Environmental Stability 6. Advanced Manufacturing Techniques 1. Aerospace Applications 2. Electric Vehicles (EVs) 3. Renewable Energy Systems 4. Consumer Electronics 5. Telecommunications Success Stories ConclusionThe development of niobium oxide capacitors, such as the CFR-50JB-52-1R2, highlights the potential of advanced materials to enhance capacitor performance across various industries. Their unique properties, combined with ongoing advancements in manufacturing and application techniques, position them as a key technology in the future of electronic components. As industries continue to demand higher efficiency and reliability, niobium oxide capacitors are poised to play an increasingly important role in the development of next-generation electronic systems, paving the way for innovations in energy management, telecommunications, and beyond.

Core Functional Technologies of Thin Film Capacitors1. High Dielectric Constant Materials: Thin film capacitors utilize materials such as tantalum, aluminum oxide, and high-k dielectrics, which allow for increased capacitance in a smaller footprint. This is particularly advantageous in applications where space is constrained, such as in mobile devices and compact electronic assemblies.

2. Low Equivalent Series Resistance (ESR): The low ESR characteristic of thin film capacitors is crucial for high-frequency applications. This property reduces energy losses during operation, enhancing the efficiency of circuits, especially in RF and microwave applications. 3. Temperature Stability: Thin film capacitors are engineered to maintain stable capacitance across a wide temperature range. This stability is essential for applications in extreme environments, such as automotive and aerospace, where temperature fluctuations can be significant.

4. Scalability: The fabrication techniques used for thin film capacitors, such as sputtering and chemical vapor deposition, allow for scalable production. This means manufacturers can produce capacitors with varying capacitance values and dimensions to meet specific design requirements.

5. Integration with Other Technologies: Thin film capacitors can be integrated with MEMS and other semiconductor technologies, enabling multifunctional devices. This integration is particularly useful in applications like sensors and actuators, where space and performance are critical.

Application Development Cases1. RF and Microwave Applications: In RF circuits, thin film capacitors are essential for tuning, filtering, and impedance matching. Their low ESR and high-frequency performance make them ideal for applications in telecommunications, satellite communications, and radar systems.

2. Power Electronics: Thin film capacitors play a vital role in power supply circuits, where they help smooth voltage fluctuations and improve overall power quality. Their compact size allows for integration into small power modules, which is increasingly important in modern electronic designs.

3. Consumer Electronics: In devices like smartphones and tablets, thin film capacitors are used for decoupling and filtering applications. Their small form factor allows for efficient use of space, contributing to the overall miniaturization of electronic devices.

4. Automotive Applications: With the growth of electric vehicles (EVs) and advanced driver-assistance systems (ADAS), thin film capacitors are increasingly utilized in automotive electronics. They are used for energy storage, signal processing, and noise filtering, enhancing the performance and reliability of automotive systems.

5. Medical Devices: In the medical field, thin film capacitors are critical components in devices such as pacemakers, diagnostic equipment, and imaging systems. Their reliability and compact size are essential for ensuring the safety and effectiveness of medical technologies.

6. Telecommunications: Thin film capacitors are employed in communication devices for signal processing and filtering. Their high performance is crucial for maintaining data integrity and ensuring efficient data transmission in high-speed networks.

ConclusionThin film capacitors represent a significant advancement in capacitor technology, offering high performance in compact sizes. Their unique properties make them suitable for a wide range of applications, from consumer electronics to automotive and medical devices. As technology continues to evolve, the demand for thin film capacitors is expected to grow, driving further innovation in materials and manufacturing processes.

Further Reading and ResourcesFor those interested in exploring more about thin film capacitors, consider the following resources:

Academic Journals: Look for articles in journals such as the *Journal of Applied Physics* or *IEEE Transactions on Electron Devices* for in-depth studies on thin film capacitor technology.Academic Journals: Look for articles in journals such as the *Journal of Applied Physics* or *IEEE Transactions on Electron Devices* for in-depth studies on thin film capacitor technology.Industry Publications: Magazines like *EDN* and *Electronics Weekly* often feature articles on the latest trends and applications in capacitor technology.Industry Publications: Magazines like *EDN* and *Electronics Weekly* often feature articles on the latest trends and applications in capacitor technology.- Technical White Papers: Many capacitor manufacturers publish white papers detailing their products' specifications, applications, and case studies, which can provide valuable insights into real-world applications.

- Conferences and Workshops: Attending industry conferences such as the *International Symposium on Power Semiconductor Devices and ICs (ISPSD)* can provide networking opportunities and insights into the latest research and developments in capacitor technology.

By leveraging these resources, engineers and designers can stay informed about the latest advancements in thin film capacitors and their applications across various industries.

CFR-25JB-52-1M1 Mica and PTFE Capacitors: Core Functional Technologies and Application Development CasesMica and PTFE (Polytetrafluoroethylene) capacitors are specialized electronic components known for their unique properties, making them suitable for a variety of demanding applications. Below, we delve into the core functional technologies and notable application development cases for these capacitors.

Core Functional Technologies 1. Mica Capacitors

- **Dielectric Properties**: Mica capacitors utilize natural mica as a dielectric material, which offers exceptional stability, low loss, and high insulation resistance. This makes them ideal for applications requiring precision and reliability.

- **Temperature Stability**: These capacitors exhibit minimal capacitance variation with temperature changes, ensuring consistent performance in environments with fluctuating temperatures.

- **High Voltage Ratings**: Mica capacitors can handle high voltages, making them suitable for RF (radio frequency) applications and high-frequency circuits where voltage stability is critical.

- **Low ESR (Equivalent Series Resistance)**: The low ESR of mica capacitors is essential for high-frequency applications, allowing for efficient energy transfer and minimal signal distortion. 2. PTFE Capacitors

- **Chemical Resistance**: PTFE capacitors are renowned for their excellent chemical resistance, making them suitable for use in harsh environments, including industrial and chemical processing applications.

- **Low Loss Factor**: With a low loss factor, PTFE capacitors are ideal for high-frequency applications, ensuring minimal energy loss and maintaining signal integrity.

- **Wide Temperature Range**: Similar to mica capacitors, PTFE capacitors can operate effectively over a broad temperature range, making them versatile for various applications.

- **Mechanical Stability**: The mechanical robustness of PTFE capacitors ensures durability and reliability in demanding conditions, such as those found in aerospace and military applications. Application Development Cases 1. Telecommunications

- **RF Amplifiers**: Mica capacitors are extensively used in RF amplifiers due to their high stability and low loss characteristics, which help maintain signal integrity in communication systems.

- **Filters**: Both mica and PTFE capacitors are integral to filter circuits, eliminating unwanted frequencies and ensuring clear signal transmission in telecommunication devices. 2. Aerospace and Defense

- **High-Temperature Applications**: Mica capacitors are critical in aerospace applications where high reliability and temperature stability are essential, such as in radar systems and satellite communications.

- **Military Equipment**: PTFE capacitors are employed in military applications due to their chemical resistance and ability to withstand harsh environmental conditions, ensuring reliable performance in the field. 3. Industrial Equipment

- **Power Supplies**: Mica capacitors are commonly used in power supply circuits for their high voltage ratings and stability, ensuring reliable operation in industrial machinery and equipment.

- **Motor Drives**: PTFE capacitors are utilized in motor drive applications to filter out electrical noise and improve overall efficiency, contributing to better performance in industrial automation. 4. Medical Devices

- **Diagnostic Equipment**: Mica capacitors are found in medical diagnostic equipment where precision and reliability are paramount, such as in imaging systems and laboratory instruments.

- **Patient Monitoring Systems**: PTFE capacitors are used in patient monitoring systems due to their stability and low loss characteristics, ensuring accurate readings and reliable operation. 5. Consumer Electronics

- **Audio Equipment**: Mica capacitors are often incorporated into high-end audio equipment to ensure high fidelity and low distortion in sound reproduction, enhancing the listening experience.

- **Television and Display Technologies**: PTFE capacitors are utilized in display technologies for their low loss and high-frequency performance, contributing to improved image quality and responsiveness. ConclusionMica and PTFE capacitors are vital components in a wide range of high-performance applications due to their unique properties. Their ability to maintain stability under extreme conditions makes them invaluable in telecommunications, aerospace, industrial, medical, and consumer electronics sectors. As technology continues to evolve, the demand for these capacitors is expected to grow, leading to further innovations and expanded applications in the field. The ongoing development of new materials and manufacturing techniques will likely enhance the performance and capabilities of mica and PTFE capacitors, solidifying their role in future electronic designs.

Application Development in Film Capacitors for CFR-50JB-52-1M1: Key Technologies and Success StoriesFilm capacitors, such as the CFR-50JB-52-1M1, are integral components in a wide range of electronic applications due to their superior electrical properties, stability, and reliability. Below, we explore key technologies that have advanced the development of these capacitors, along with notable success stories that illustrate their impact across various industries.

Key Technologies1. Material Innovations2. Dielectric Layer Design3. Manufacturing Techniques4. Thermal Management5. Simulation and Modeling1. Renewable Energy Systems2. Electric Vehicles (EVs)3. Consumer Electronics4. Industrial Automation5. Telecommunications Success Stories ConclusionThe application development of film capacitors like the CFR-50JB-52-1M1 is propelled by advancements in materials, manufacturing techniques, and design innovations. Their success across diverse industries—including renewable energy, automotive, consumer electronics, industrial automation, and telecommunications—underscores their versatility and significance in modern technology. As the demand for more efficient and reliable electronic components continues to rise, film capacitors will remain pivotal in shaping the future of electronic design and application.

Electric Double Layer Capacitors (EDLCs) OverviewElectric Double Layer Capacitors (EDLCs), commonly referred to as supercapacitors, are advanced energy storage devices that combine the characteristics of traditional capacitors and batteries. They are known for their ability to store significant amounts of energy and deliver it rapidly, making them ideal for a wide range of applications. Below, we delve into the core functional technologies that underpin EDLCs and explore various application development cases that highlight their effectiveness.

Core Functional Technology of EDLCs1. Electrochemical Double Layer Formation2. High Surface Area Electrodes3. Electrolyte Composition4. Hybrid Systems5. Advanced Manufacturing Techniques1. Electric Vehicles (EVs)2. Renewable Energy Systems3. Consumer Electronics4. Industrial Applications5. Smart Grids6. Wearable Technology Application Development Cases ConclusionElectric Double Layer Capacitors (EDLCs) represent a significant advancement in energy storage technology, offering unique advantages such as high power density, long cycle life, and rapid charge/discharge capabilities. Their versatility allows for applications across various industries, from automotive to consumer electronics, and they are increasingly being integrated into hybrid systems to enhance overall performance. As research and development continue, the potential for EDLCs to contribute to sustainable energy solutions and innovative technologies remains vast, paving the way for a more energy-efficient future.

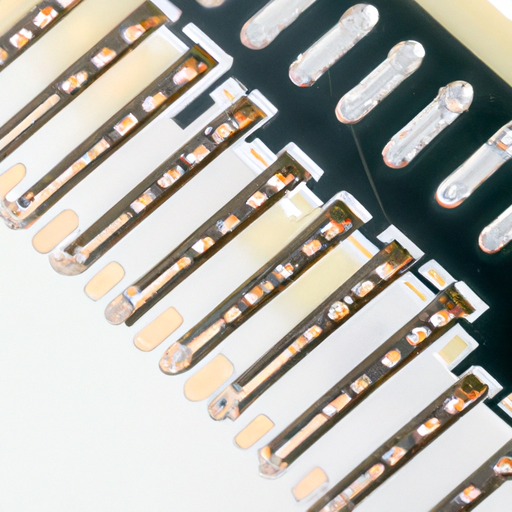

Application Development in Ceramic Capacitors for CFR-50JB-52-1K1: Key Technologies and Success StoriesCeramic capacitors, such as the CFR-50JB-52-1K1, are integral components in modern electronics, known for their reliability, stability, and performance. The development and application of these capacitors involve several key technologies and methodologies that enhance their functionality across various industries. Below are insights into these technologies and notable success stories.

Key Technologies1. Material Science Innovations2. Manufacturing Techniques3. Simulation and Modeling4. Quality Control and Testing5. Integration with Other Components1. Consumer Electronics2. Automotive Applications3. Telecommunications4. Medical Devices5. Industrial Applications Success Stories ConclusionThe application development of ceramic capacitors like the CFR-50JB-52-1K1 is propelled by advancements in materials, manufacturing technologies, and integration techniques. The success stories across various industries underscore the versatility and reliability of ceramic capacitors, making them essential components in modern electronic devices. As technology continues to evolve, the role of ceramic capacitors is expected to expand, leading to further innovations and applications that will shape the future of electronics.

Tantalum Capacitors: Core Functional Technology and Application DevelopmentTantalum capacitors are integral components in modern electronics, known for their high capacitance per volume, stability, and reliability. While the MM74HC4020N is a binary counter IC that does not directly utilize tantalum capacitors, understanding the role of these capacitors in circuits that may incorporate such ICs is essential for effective design and application. Below, we explore key articles and application cases that highlight the effective use of tantalum capacitors.

Core Functional Technology Articles1. Understanding Tantalum Capacitors: Basics and Benefits2. Tantalum Capacitors in Power Supply Applications3. Reliability and Failure Mechanisms of Tantalum Capacitors4. Tantalum Capacitors in RF and High-Frequency Applications5. Emerging Trends in Tantalum Capacitor Technology1. Smartphone Power Management2. Automotive Electronics3. Medical Devices4. Telecommunications Infrastructure5. Consumer Electronics Application Development Cases ConclusionTantalum capacitors are essential components in various electronic applications, offering benefits such as high capacitance, reliability, and stability. Understanding their technology and application cases can aid engineers and designers in making informed decisions when integrating these components into their designs, including those involving ICs like the MM74HC4020N. As technology continues to advance, the role of tantalum capacitors is expected to expand, solidifying their position as a critical element in future electronic innovations.

Application Development in Aluminum Electrolytic Capacitors for CFR-50JB-52-1R1: Key Technologies and Success StoriesAluminum electrolytic capacitors, such as the CFR-50JB-52-1R1, are integral components in a multitude of electronic applications due to their high capacitance values, cost-effectiveness, and versatility. The development and application of these capacitors are driven by several key technologies and methodologies that enhance their performance, reliability, and applicability across various industries. Below, we explore these key technologies and highlight notable success stories.

Key Technologies1. Electrolyte Formulation2. Anodization Techniques3. Foil Technology4. Construction and Packaging Innovations5. Simulation and Modeling6. Quality Control and Testing1. Consumer Electronics2. Automotive Applications3. Renewable Energy Systems4. Industrial Automation5. Telecommunications Success Stories ConclusionThe development of aluminum electrolytic capacitors like the CFR-50JB-52-1R1 is characterized by a combination of advanced materials, innovative manufacturing processes, and stringent testing protocols. As technology continues to evolve, these capacitors will play an increasingly vital role in a diverse array of applications, from consumer electronics to renewable energy systems. The success stories across various industries underscore the versatility and reliability of aluminum electrolytic capacitors, solidifying their status as essential components in modern electronic design.

Overview of Chassis Mount Resistors: CFR-25JB-52-1MChassis mount resistors, such as the CFR-25JB-52-1M, are integral components in electronic circuits, providing essential resistance in a compact and robust form factor. Their design and functionality cater to a wide array of applications, making them indispensable in modern electronics. Below, we delve into the core functional technologies and application development cases that underscore the effectiveness of chassis mount resistors.

Core Functional Technologies1. High Power Handling2. Thermal Management3. Precision and Stability4. Durability and Reliability5. Versatile Mounting Options1. Power Supply Circuits2. Motor Control Systems3. Audio Equipment4. Industrial Automation5. Telecommunications6. Automotive Applications Application Development Cases ConclusionChassis mount resistors like the CFR-25JB-52-1M are fundamental components in a variety of electronic applications due to their high power handling, effective thermal management, precision, and durability. Their versatility allows for effective integration into power supplies, motor control systems, audio equipment, industrial automation, telecommunications, and automotive applications. As technology continues to advance, the demand for reliable and efficient chassis mount resistors will grow, solidifying their role as a cornerstone in modern electronic design.

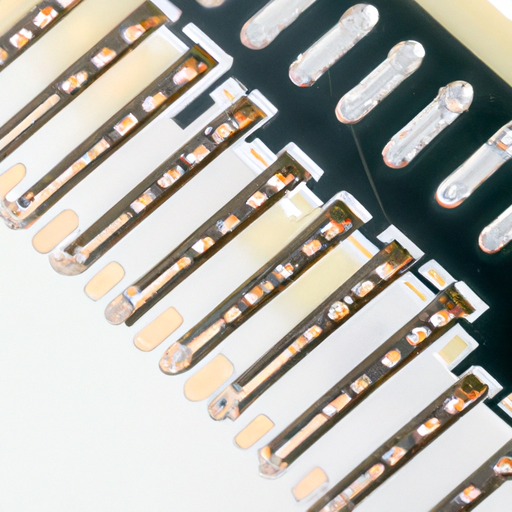

Application Development in Through-Hole Resistors for CFR-50JB-52-1M: Key Technologies and Success StoriesThrough-hole resistors, such as the CFR-50JB-52-1M, are integral components in a wide range of electronic applications due to their reliability, stability, and ease of handling during assembly. Below, we explore key technologies that enhance their performance and some notable success stories that highlight their application across various industries.

Key Technologies1. Material Science2. Manufacturing Techniques3. Thermal Management4. Testing and Quality Control5. Simulation and Modeling1. Consumer Electronics2. Industrial Applications3. Automotive Electronics4. Medical Devices5. Telecommunications Success Stories ConclusionThrough-hole resistors like the CFR-50JB-52-1M are vital components in various electronic applications, thanks to their reliability, ease of handling, and performance characteristics. Advancements in material science, manufacturing techniques, and testing methods have further enhanced their applicability across diverse industries, from consumer electronics to medical devices. As technology continues to evolve, the role of through-hole resistors will remain significant in ensuring the performance and reliability of electronic systems, paving the way for innovative applications in the future.